When the surface strength of corrugated packaging cartons is poor, they are prone to pulverization, fuzzing, blistering and peeling when printing. Powder shedding refers to the powdery materials falling from the paper surface during printing, such as paint, filler, pigment, etc. Fluff refers to the peeling of fibers on the paper surface from the paper surface during printing. The following measures can be taken to reduce or avoid the chance of falling, fuzzing, blistering and peeling of corrugated packaging carton paper powder.

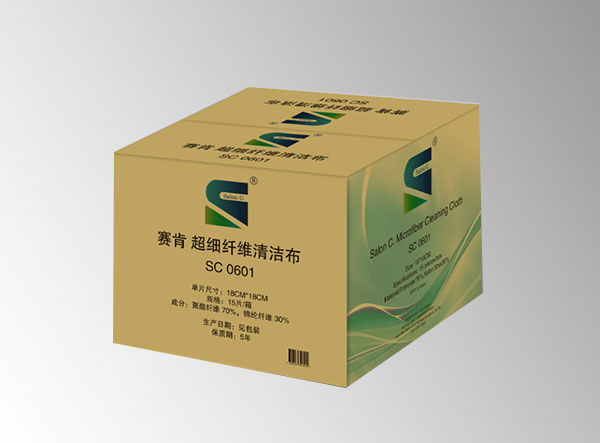

Corrugated packing carton

1 Adjust the viscosity of the ink: If the paper with poor surface strength is printed with high viscosity ink, it is easy to have quality problems, such as powder loss, fuzzing, blistering and peeling. Therefore, additives suitable for the printing process conditions can be selected, and the fluidity and viscosity of the ink can be adjusted to reduce the adhesion of the ink layer on the paper surface and the peel tension in the printing process.

2 Adjust the printing pressure: If the printing pressure of corrugated packaging carton is too light or uneven, the ink layer on the layout will not be transferred to the paper completely and evenly, so printing and blooming are easy to occur. However, if the printing pressure of corrugated packaging carton is too high, it is easy to damage the coating and fiber structure on the paper surface, and it is easy to cause powder quality, hair loss, blistering and peeling quality problems. Therefore, the use of uniform and appropriate printing pressure is an important condition for good ink transfer, and also one of the technical means to prevent undesirable problems.

Create good production orders and environment. Keeping the production site clean is also an essential condition to ensure the quality of cartons. For example, the working area, the stacking and transportation of equipment and products, the working environment of workers and the cleanliness of the site have an important impact on the quality of food packaging cartons. There should be regulations. Therefore, the points and points on the production site of food packaging cartons can be effectively controlled.

Measures that can be used: formulate the on-site management standards for the production of cartons for food packaging, and regularly check and evaluate the site, machinery, equipment, raw materials, in-process products, workstations and equipment. Effective measures to reduce the damage caused by bumping, scraping, pollution and rough handling in the process of handling cartons. Semi finished products and in-process products must be labeled: especially if the cardboard line is not printed on the product, if it is not listed in the case of similar varieties and specifications, it is easy to cause confusion and errors.